What is the full form of TMT?

TMT involves Thermo Mechanical Treatment of ribbed bars where plastic deformation is carried out to effect phase transformation. Over lapping of heat treatment and mechanical deformation occurs.

TMT is the backbone of any good construction. Be it a big flyover or your dream home, choosing superior quality TMT is very important to hold your construction for a long time. You need to be aware of the following facts in order to make the right decision.

TMT involves Thermo Mechanical Treatment of ribbed bars where plastic deformation is carried out to effect phase transformation. Over lapping of heat treatment and mechanical deformation occurs.

Controlling factors for effective TMT manufacturing are:

Yes, Maithan Steel is BIS approved and it conforms to IS 1786 grade Fe-600.

Yes, physical & chemical properties of Maithan Fe-600 HD bar are within the specified limit of IS 1786:2008 (Please refer to the Physical and Chemical Properties Chart of Maithan Steel)

Customer should prefer Maithan Steel for these reasons:

Stringent quality control beyond the BIS specification, raw material to finished product under the same shed, full control over raw material, monitoring by qualified engineers and moderate price with effective after sales network.

Quality Maithan TMT 600 is made from superior quality billet, not ingot, with appropriate chemical composition & dimension as suitable for making quality TMT bar.

Yes, control on raw material is essential for quality of TMT bar.

Each and every billet must have cast number for the sake of traceability. Billets which have deviated from the specified limit of chemistry must be segregated out from the tested lot.

Manganese, a metallic alloying elements with much larger atom than carbon, forms a substitutional solid solution when added by displacing iron atom. Manganese blocks the mechanical movements of the iron lattices and thereby improve the strength and hardness of steel. Silicon can also cause a substitutional solid solution to form by occupying iron lattices. Silicon increases strength and hardness of steel, although it is less effective than manganese. Both silicon and manganese reduces red-shortness in steel, which means its brittleness at high temperature usually caused due to high sulphur content.

Phosphorus imparts cold shortness. Increase in phosphorus content increases the tensile strength but sharply reduces impact strength and ductility of steel.

Sulpher forms the chemical compound FeS with iron which is practically insoluble in solid iron. The presence of FeS in the grain boundaries and the fact that it may actually melt at rolling temperature and break up the continuity of steel grain is the reason for red-shortness.

For low carbon steel, carbon equivalent is practically = %c + % Mn/6

Carbon equivalent value is used to understand how the residuals and different alloying elements affect the strength of steel and elongation of the bar. It has been revealed that a consistent yield strength and elongation of each TMT bar of a set can be achieved by having the carbon equivalent value in the range 0.37< C.E<0.40.

Proportion of martensitic depends on degree of quenching. By increasing the water pressure and the length of quenching tube, the martensite area can be increased. Higher percentage of carbon gives higher martensitic growth.

It is water quenching which is responsible for transformation of Austenite into martensitic. Austenite above 910°C when super cooled by water quenching, it transform into martensitic in such a way that martensitic is found in the periphery region of the bar section leaving the core section hot. Heat retained in core section tempers the peripheral martensitic into tempered martensitic. Core portion transforms into pearlite. Maithan TMT600 is quenched with R.O water

If a TMT bar is saw-cut, it can be felt that in the rim portion it is hard, but after that in the core portion it is ductile. So an actual TMT bar is not ductile throughout the section.

Yes, Maithan TMT 600 is very competitively priced in comparison to other TMT Bars.

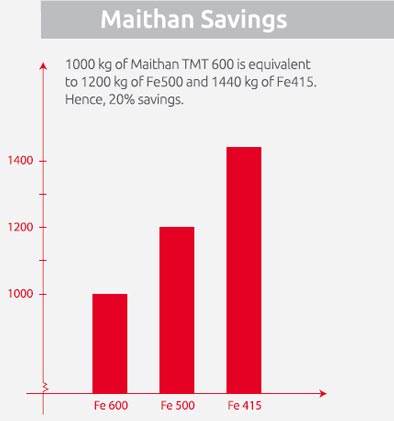

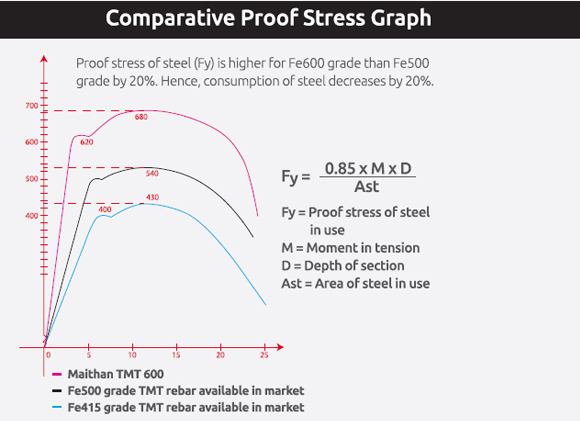

Maithan TMT600 has arisen out after stringent quality control. In general, ductility is inversely proportional to the strength. Yield strength and UTS of Maithan TMT600 is much higher than the specified minimum value without affecting the ductility and percentage of elongation. This unique combination has enabled our product to be used as Earthquake resistant bar as well as corrosion resistant steel bar. 20% less steel is needed to achieve the desired strength to any construction, in comparison to other grades of TMT.

Price of our product still moderate. Without deviating BIS specification, we always maintain the unit mass of our product in the lowest side. Unit mass in lower means length of the bar per MT is longer, which offers 3-5% benefit to the customer.

Yes, we have established a quality plan and maintain that in our everyday routine manufacturing job. We also review that quality plan after certain interval.

Maithan Steel also makes binding wires in name of Maithan Linkon, and also Stirrups.